| Sign In | Join Free | My fnxradio.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My fnxradio.com |

|

Brand Name : SUSSMAN

Model Number : SS-BD

Certification : SGS,CE ,ISO9001

Place of Origin : China

MOQ : 1 set

Price : negotiable

Payment Terms : L/C, T/T,

Supply Ability : 10 sets per month

Delivery Time : 60-90 working days

Packaging Details : Standard Packing with film coated and steel wire fixed

Name : Type B Floor Deck Roll Forming Machine

Material Thickness : 0.8-1.2mm

Forming Stations : 28 stations

Dirve System : Chain drive

Working Speed : 0-12m/min

Main Motor Power : 15Kw*2 Kw

0.8mm-1.2mm Thickness B Composite Metal Double Deck Floor Roll Forming Machine

The metal deck is a steel structure building material produced by cold roll forming, which is used for supporting floor concrete in the construction industry. It is also called a metal floor deck.

Steel decking products are the preferred method of floor construction for multi-story structural steel framed buildings. Floor deck offers structural engineers and contractors a versatile and cost-effective composite steel flooring solution. The advantages of the metal deck rollforming machines are a high wave, high strength, high automation and low cost.

The normal machinable thickness range of our steel deck roll forming machine is 0.8-1.2mm, the standard or more used in international market is Gauge 22, 20, 18, 16 (0.75-1.5mm), working raw material is PPGI, Galvanized steel etc. We confirm machine’s configuration according to your drawing, specially the pitch and height of each wave. Sussman Machinery is always your best choice of metal deck roll forming machine.

Floor Deck Making Machine Technical Parameter

Machine List

| 10 tons de-coiler with coil car and arm device | 1 set |

| Feeding with guide | 1 set |

| Main roll forming machine | 1 set |

| Hydraulic cutting | 1 set |

| Control box | 1 unit |

| Hydraulic station | 1 unit |

| 4 meters passive out table | 1 set |

| Safety cover | 1 set |

| Spare parts | 1 package |

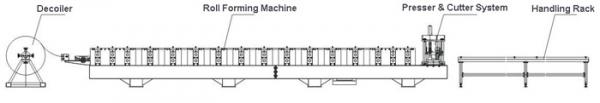

Working Flow of Machine

Uncoiling—Feeding&Leveling--Roll forming—Cutting—Products collecting

Standard Profile Drawing of product

Machine Photo

Our service

1. Professional mechanical background sales for better undestanding customer's need

2. Experienced in China machine industry for supplying comprehensive machines and equipments

3. Strictly product manufacturing and quality controlling to ensure every machine we sold is satisfied with our customer

4. Engineers available to service machine overseas, for example installation, training, etc

5. Lifelong service for spares, ware parts, technical supporting, etc

Maintance and the service of the machine

Daily maintenance with meticulous care plays an important part in extension the equipments’ operation time and the quality of rolling plank. Therefore, please do the following things in your daily

1.The hydraulic tank must be filled with 32# or 46# hydraulic oil before using. The amount of oil is subject to the oil mark

2. Add and daub lube often to the outside parts. (Such as driving chain,Scissors, gears, rollers, )

3. Wipe the surface dust of roller often and particularly work outside. If you do not use it for long time ,you should daub

machine and lube in the roller surface and you need clean it when you use next time.

4. If the equipment does not use for long time, you should use plastics cloth or other articles to cover it and notice to avoid

rain and damp, especially electrical controlling box

5. Cutting device should add lube to the places where need lube to the request

6. Usually look into hydraulic station and the oil quantity of deceleration machine, you should add in time when oil quantity

shortage

7. Electrical components should be guaranteed to work in a dry environment, such as damp. Rain should continue to work after drying.

|

|

B Deck Floor Roll Forming Machine 0.8 - 1.2mm Double Layer Type Images |